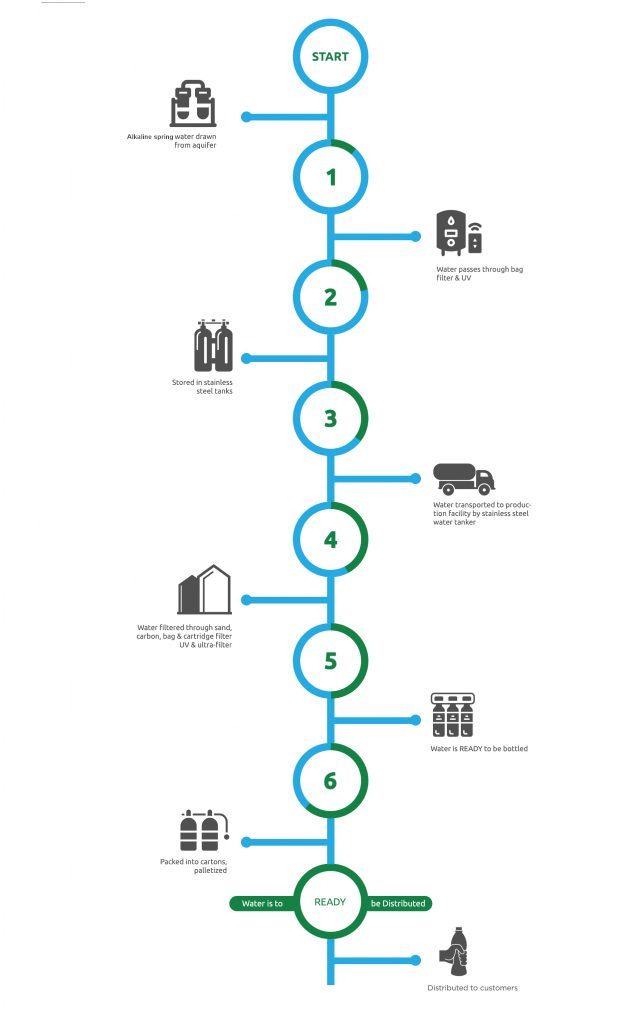

Purification & Production Process

Purification & Production Process

Quality Standards

Quality Standards

- At Refresh Darwin we give utmost importance to quality and believe in maintaining the highest possible standards in hygiene.

- All our staff are required to adhere to and maintain strict personal hygiene procedures in and around the production area.

- We use NATA certified third party labs to ensure that every product coming off the conveyor belt has met the HACCP quality guidelines.

- Samples of our water are collected and treated every month and regular quality tests are performed on random samples of all pack sizes collected from products on the shelves, nationwide.

- All of our facilities are HACCP certified and the processing plant operates under a policy of green initiatives.

- Our PET bottles are blown on site to reduce wastage and leaving a large carbon footprint on the local environment

- Refresh Darwin also runs a full grey water system that recycles any water so it’s not lost or wasted. There is a treatment plant on site that treats any unused water so that it can be used through reticulation.

- 30kW of solar panels installed to reduce our carbon footprint.